Antheia’s Head of Commercialization, Richard Sherwin on DCAT Week 2025

This week the Drug, Chemical & Associated Technologies Association (DCAT) will host DCAT Week 2025 in New York City, an annual event bringing together companies from across the bio/pharmaceutical manufacturing value chain. We sat down with Richard Sherwin, Antheia’s SVP of Commercialization, to learn more about the importance of the event for the future of […]

Antheia’s 2024 in Review: A Year Of Collaboration

As we reflect on 2024, it’s been a significant year of collaboration, with every Antheia employee and partner helping us move closer toward our mission of transforming pharmaceutical supply chains and ending essential medicine shortages. No one person, company, or organization can solve a daunting global problem like drug shortages alone, but we have made […]

Antheia Secures Second Project Agreement with the BioMaP-Consortium Valued at up to $12M

Company awarded for its ability to outperform conventional manufacturing methods for critical pharmaceutical ingredients and rapidly reach commercial scale in the U.S.

Pharma isn’t ready for OTC Narcan demand

Today’s blog will focus on Narcan, a critical opioid overdose rescue drug that is produced from thebaine, Antheia’s first commercial-scale, biomanufactured pharmaceutical ingredient. Read on for more on recent efforts to make Narcan available over the counter, as well as the challenges and opportunities this policy change presents for the pharma industry.

Antheia Announces New Funding to Support Domestic Production of Critical Pharmaceutical Ingredients

Company awarded government project agreement to onshore key pharmaceutical supply chains, alongside strategic investment from In-Q-Tel and Echo

Addressing a Root Cause of Global Drug Shortages

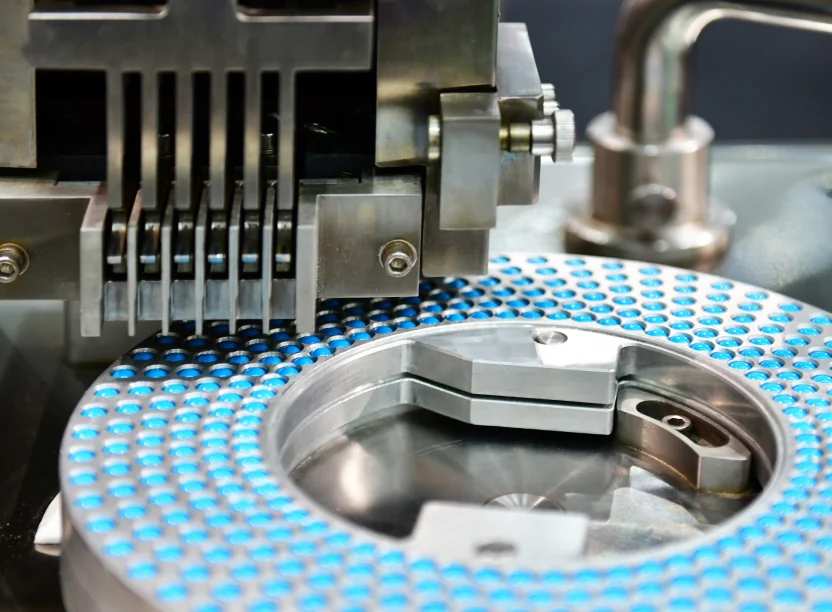

The years-long journey medicines take from the farm to the pharmacy is a delicate one, vulnerable to extreme weather, mechanical failures, logistical and shipping delays, and geopolitical issues.

Antheia CEO Keynotes at OECD Global Forum on Technology: Building our Bio Future

Last week, Antheia CEO and co-founder, Dr. Christina Smolke joined OECD’s Global Forum on Technology: Building our Bio Future as a keynote speaker. OECD (Organization for Economic Co-operation and Development) is an international organization bringing together government, academia, and industry to build global policies that foster prosperity and well-being for all. In her keynote address, […]

Future of Pharma Insights: Q&A with Olon Group

We sat down with Andrea Conforto, VP of CDMO at Olon Biotech.

PharmaSource: Antheia and Olon Extend Biomanufacturing Partnership

Antheia and Olon have announced a continuation of partnership, leveraging Olon’s fermentation infrastructure for the manufacture of Antheia’s early products

Antheia and Olon Continue Partnership for Biomanufacturing Antheia’s Pipeline of KSMs and APIs for Essential Medicines

Antheia and Olon established this partnership in 2022 to leverage Olon’s fermentation sites across Italy. Olon has since played a pivotal role as a CDMO for scaling Antheia’s biomanufacturing processes and producing its Biosynthetic KSMs (key starting materials) and APIs.