Celebrating Antheia’s Series C Financing

After a busy year marked by major commercial milestones for Antheia, we are excited to announce $56 million in Series C financing. With the support of new and existing investors, we are entering a new chapter as a business, bringing us closer than ever to a world without essential medicine shortages.

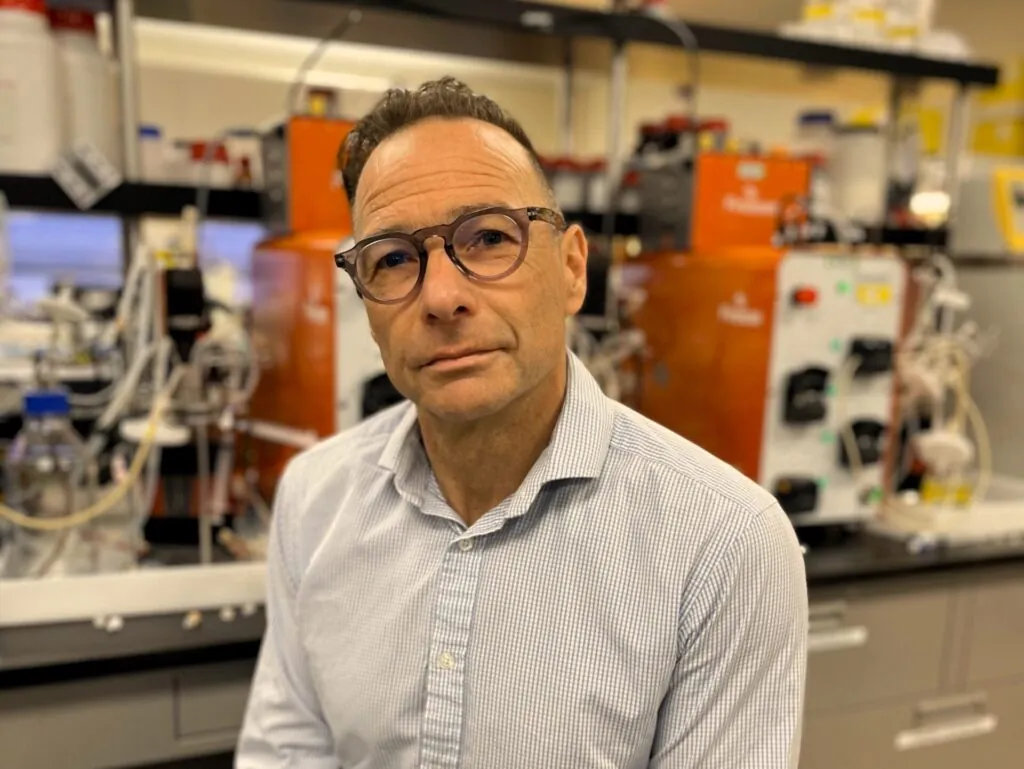

Antheia’s Head of Commercialization, Richard Sherwin on DCAT Week 2025

This week the Drug, Chemical & Associated Technologies Association (DCAT) will host DCAT Week 2025 in New York City, an annual event bringing together companies from across the bio/pharmaceutical manufacturing value chain. We sat down with Richard Sherwin, Antheia’s SVP of Commercialization, to learn more about the importance of the event for the future of […]

Introducing Farrah Pulce, Head of Project Management

In today’s blog, we are pleased to introduce Farrah Pulce, Head of Project Management at Antheia. Farrah helps every team across the company stay on track toward our collective goals, and her work played a crucial role in our first commercial delivery of thebaine. We sat down with Farrah to learn more about her background […]

Celebrating International Day of Women and Girls in Science

Today is the 10th anniversary of UNESCO’s International Day of Women and Girls in Science. We know first hand that when we bring together a diverse team with a wide range of perspectives and experiences, we can solve some of the world’s biggest problems. To celebrate both the legacy and the future of women in […]

Antheia’s 2024 in Review: A Year Of Collaboration

As we reflect on 2024, it’s been a significant year of collaboration, with every Antheia employee and partner helping us move closer toward our mission of transforming pharmaceutical supply chains and ending essential medicine shortages. No one person, company, or organization can solve a daunting global problem like drug shortages alone, but we have made […]

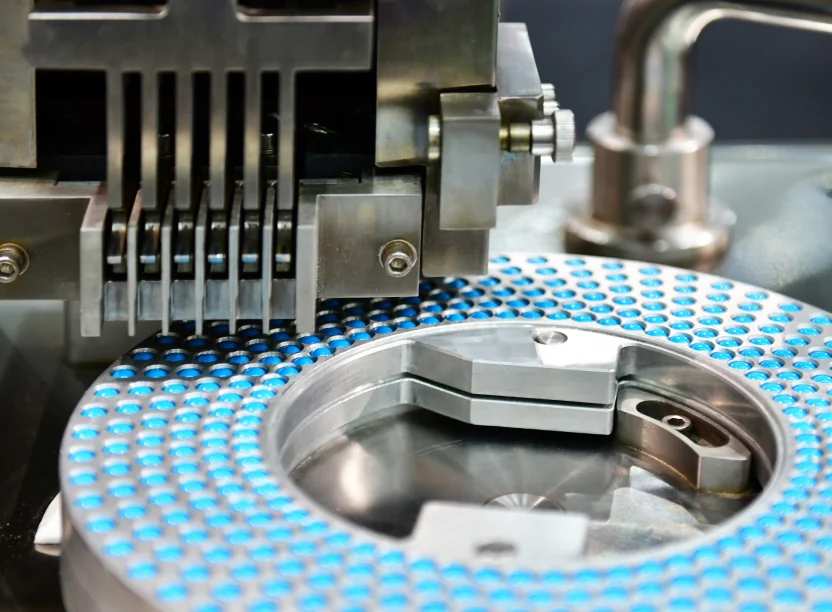

Pharma isn’t ready for OTC Narcan demand

Today’s blog will focus on Narcan, a critical opioid overdose rescue drug that is produced from thebaine, Antheia’s first commercial-scale, biomanufactured pharmaceutical ingredient. Read on for more on recent efforts to make Narcan available over the counter, as well as the challenges and opportunities this policy change presents for the pharma industry.

Introducing Ben Kotopka, Director of Data Science

Ben’s work enables teams across the business to track and make sense of more than a decade of R&D data.

Addressing a Root Cause of Global Drug Shortages

The years-long journey medicines take from the farm to the pharmacy is a delicate one, vulnerable to extreme weather, mechanical failures, logistical and shipping delays, and geopolitical issues.

Antheia at SynBioBeta 2024: Scaling Highly Engineered Strains

Antheia was a proud sponsor of this year’s SynBioBeta, the Global Synthetic Biology Conference hosted annually in the San Francisco Bay Area.

Introducing Pavel Aronov, Senior Director, Bioanalytics

Pavel and his team have developed the processes to accurately measure the quantity of our biosynthetic KSMs and APIs produced via biomanufacturing, which is no small feat when working with biological products