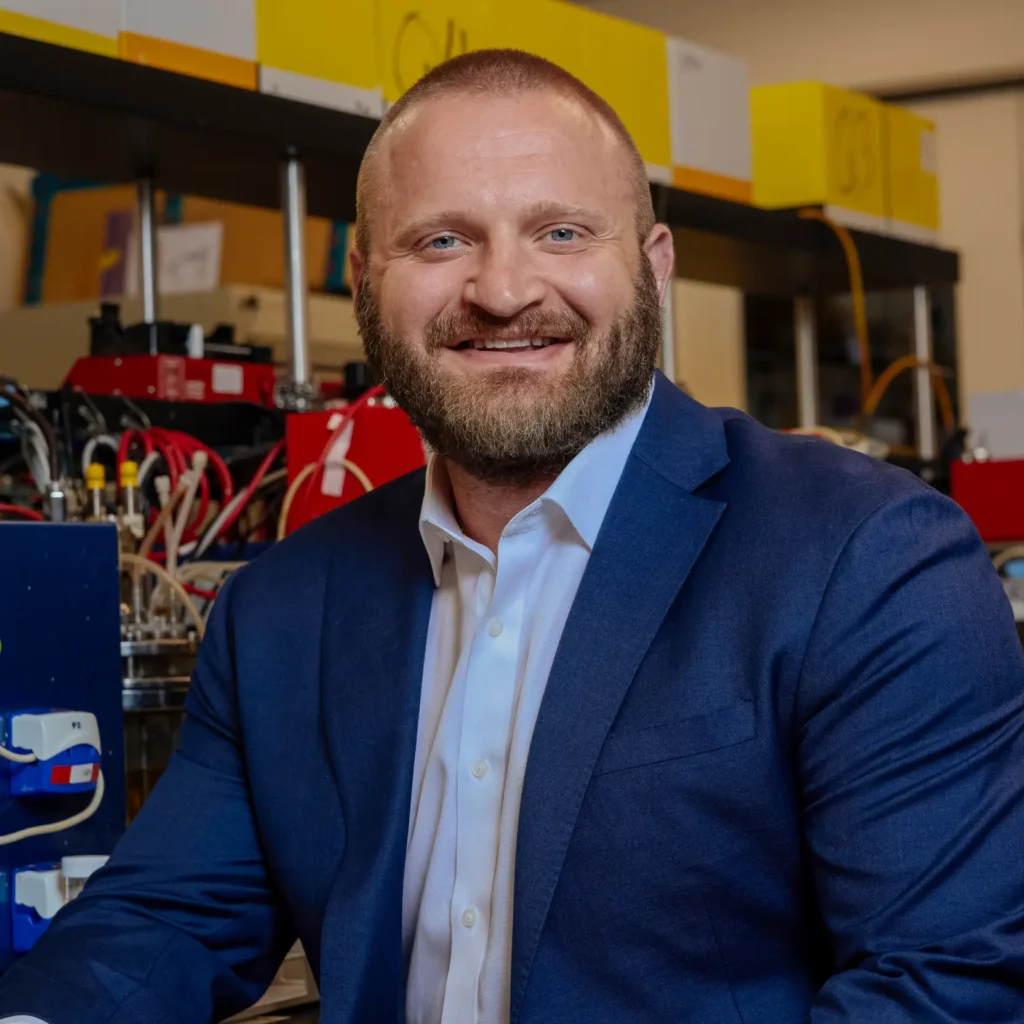

Introducing Walter Tamulis, Senior Staff Engineer, MSAT

Antheia’s recent commercial breakthrough required the effort of many technical experts who contributed countless hours of hard work. In today’s blog, we are pleased to introduce Walter Tamulis, Senior Staff Engineer of MSAT, a key member of the operations team who was essential in executing our first 116,000L scale run of thebaine and subsequent validation […]