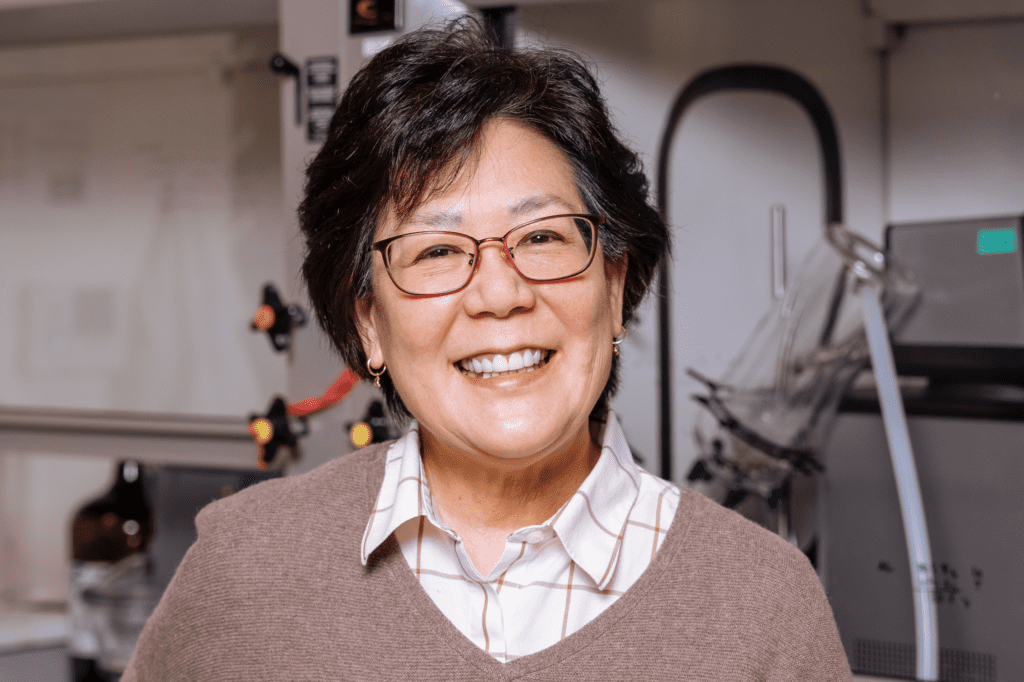

Introducing Suzanne Sato, Antheia’s Head of Downstream Processing

As the Head of Downstream Processing, Suzanne Sato leverages her 19 years of experience to lead downstream chemistry processes at Antheia. Her ability to keep the big picture in focus while working collaboratively with various teams is central to the success of Antheia’s mission. Suzy recently sat down for a Q&A in which she shares […]